Trusted Packaging Machine Repair Service for Long-Lasting Equipment Efficiency

Trusted Packaging Machine Repair Service for Long-Lasting Equipment Efficiency

Blog Article

Understanding the Key Parts and Fixing Methods for Packaging Maker Maintenance

Reliable upkeep of packaging makers rests on a detailed understanding of their vital elements, consisting of the frame, drive system, and sealing mechanisms. Acknowledging common upkeep issues, coupled with the application of preventative techniques and troubleshooting methods, can significantly boost maker dependability. Additionally, the choice of repair service practices, consisting of using OEM parts and the importance of licensed specialists, plays a critical role in lessening downtime. To truly understand the ins and outs of these systems and their maintenance, one must think about the broader effects of disregarding these vital techniques.

Trick Components of Product Packaging Machines

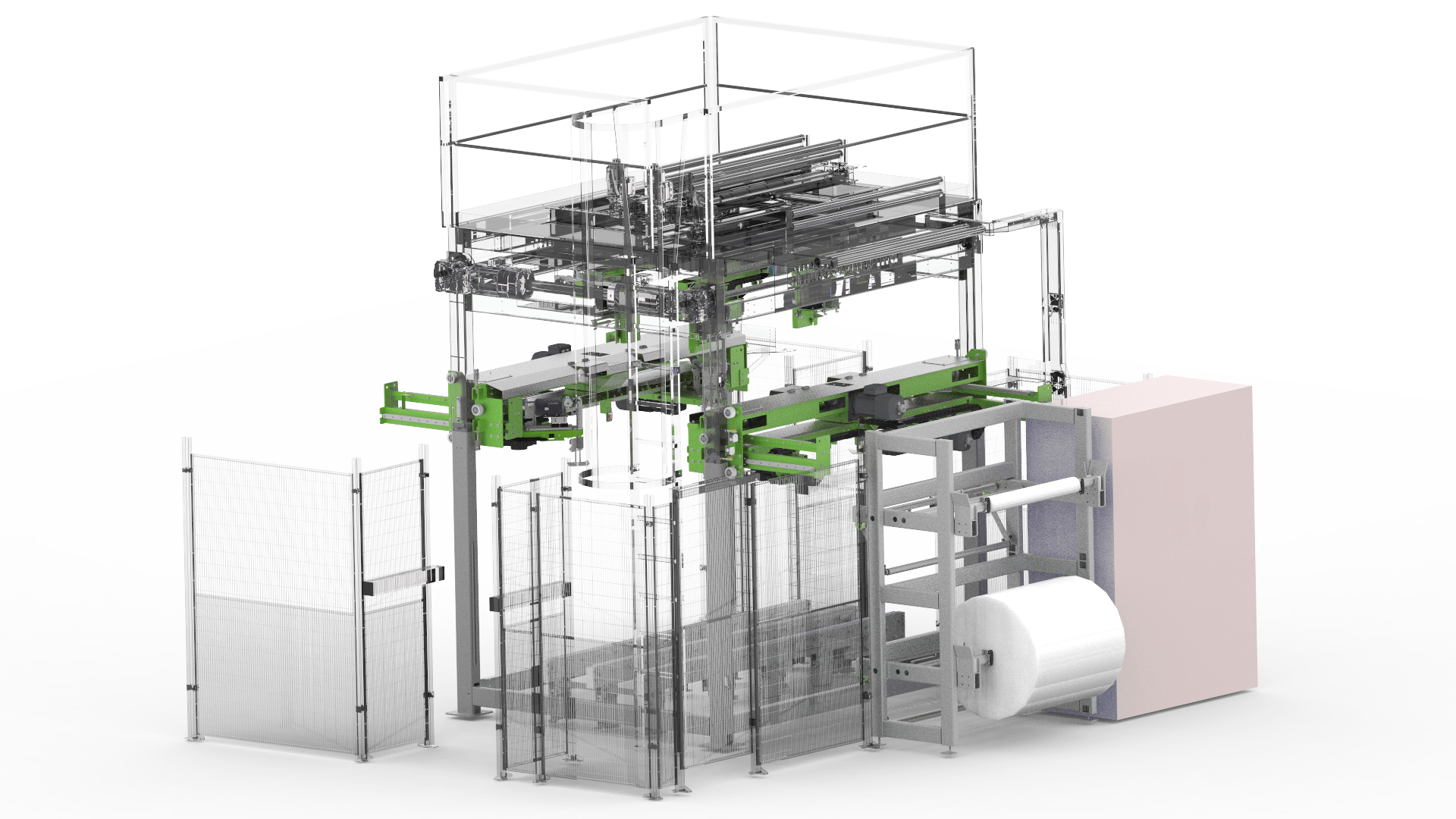

Product packaging equipments include numerous key components that function together to make certain reliable and reliable packaging processes. At the core of these machines is the structure, which supplies structural stability and houses the different operating components. The drive system, usually a combination of electric motors and equipments, assists in the motion of elements, allowing accurate procedure throughout the packaging cycle.

One more necessary element is the conveyor system, which transfers products with different phases of the product packaging procedure. This is frequently complemented by sensing units and controls that check the setting and rate of products, ensuring synchronization and lessening errors. The filling up system is essential for accurately dispensing the right quantity of item into packages, whether in liquid, powder, or strong form.

Sealing systems, including heat sealants or sticky applicators, play a vital duty in safeguarding bundles, avoiding contamination and extending life span. In addition, classifying systems are integral for giving necessary product info, ensuring compliance with laws. Lastly, the control board, outfitted with easy to use user interfaces, enables drivers to manage device features, screen efficiency, and make adjustments as needed, making certain ideal performance and effectiveness in packaging procedures.

Common Maintenance Problems

Reliable operation of packaging makers depends greatly on normal upkeep to protect against usual concerns that can disrupt manufacturing. Amongst these concerns, mechanical damage is prevalent, particularly in elements like conveyors, electric motors, and seals, which can lead to unexpected downtimes. Furthermore, imbalance of components can result in ineffective procedure, creating items to be inaccurately packaged or damaged throughout the procedure.

An additional typical upkeep concern involves the accumulation of dirt and particles, which can hinder the maker's sensing units and moving components. packaging machine repair service. This not only influences performance but can additionally position safety risks. Lubrication failures can lead to boosted rubbing, resulting in getting too hot and eventual part failing.

Electrical problems, typically coming from loosened connections or worn-out electrical wiring, can disrupt machinery functions, leading to considerable production hold-ups. Software problems due to improper configurations or outdated programs can impede the equipment's procedure, demanding instant intervention. Addressing these common maintenance concerns proactively is essential for making certain optimal efficiency and longevity of packaging machinery.

Preventative Maintenance Strategies

Applying preventative upkeep strategies is important for maintaining the efficiency and reliability of packaging machines. These strategies encompass a systematic strategy to maintenance, concentrating on the regular assessment and maintenance of equipment to preempt possible failures. By adhering to a set up maintenance program, drivers can recognize damage on components before they bring about considerable failures.

Crucial element of a preventative upkeep technique consist of regular evaluations, element, cleaning, and lubrication replacements based upon producer recommendations. Using lists can simplify this process, guaranteeing that no crucial tasks are overlooked. In addition, maintaining accurate records of upkeep tasks aids in tracking the machine's performance in time, helping with informed decision-making regarding future upkeep needs.

Educating personnel on the importance of preventative upkeep improves conformity and promotes a society of positive treatment. Carrying out an anticipating upkeep component, using information analytics and sensing unit modern technology, can even more enhance equipment performance by anticipating failures before they take place.

Fixing Strategies

When faced with breakdowns or ineffectiveness in packaging machines, employing organized troubleshooting methods is crucial for determining and fixing issues quickly. The very first step in effective troubleshooting is to develop a clear understanding of the maker's functional specifications and performance metrics. This entails examining the maker's specs, along with any kind of mistake signals or codes presented.

Next, drivers ought to carry out a visual examination, checking for apparent indications of wear, damages, or misalignment. This usually includes taking a look at belts, gears, and sensors to determine prospective root causes of his response breakdown. Collecting operational information, such as production prices and downtime logs, can also give insights helpful hints into repeating issues.

When potential problems are recognized, utilizing a sensible technique to isolate the origin reason is essential. This may need testing individual components or systems in a regulated manner. Taking part in conversations with operators who engage with the equipment routinely can generate useful feedback about unusual behaviors or patterns.

Repair and Replacement Ideal Practices

A thorough understanding of repair work and substitute finest techniques is important for maintaining the durability and performance of product packaging machines. Frequently examining the problem of equipment parts enables prompt treatment, stopping more significant concerns that can bring about pricey downtimes.

When repair work are required, it is crucial to utilize OEM (Original Equipment Manufacturer) parts to ensure compatibility and performance. This not only preserves the honesty of the machine but likewise upholds guarantee contracts. In addition, it is suggested to keep a supply of vital extra parts to facilitate quick replacements and reduce functional disruptions.

For intricate repair work, engaging certified professionals with specialized training in packaging equipment is advised. They have the know-how to diagnose issues precisely and carry out repairs efficiently. Documenting all repair service activities and parts substitutes is important for maintaining a detailed upkeep background, which can aid in future troubleshooting.

Lastly, carrying out a positive approach, consisting of regular assessments and predictive upkeep strategies, enhances the integrity of product packaging machines. By sticking to these finest methods, companies can guarantee ideal device performance, minimize Bonuses functional risks, and extend tools life-span.

Conclusion

In verdict, a comprehensive understanding of product packaging maker parts and reliable maintenance methods is important for optimum efficiency. By carrying out these techniques, organizations can ensure the long life and performance of packaging makers, inevitably contributing to enhanced operational efficiency and lowered expenses (packaging machine repair service).

Reliable upkeep of product packaging equipments hinges on a complete understanding of their vital elements, including the structure, drive system, and securing mechanisms.Reliable operation of packaging equipments depends heavily on routine maintenance to stop common problems that can interfere with production.Carrying out preventative maintenance techniques is vital for maintaining the performance and reliability of product packaging devices. Additionally, keeping accurate records of maintenance activities help in tracking the maker's performance over time, helping with educated decision-making pertaining to future maintenance demands.

Report this page